Everything Coffee- Part 1

Last Updated on February 17, 2023

Coffee bean, its origin and the post-harvesting process

Humanity runs on coffee.

2.25 billion cups of coffee are consumed worldwide every day. An estimated 125 million families are involved in growing coffee. (Our blessings for this amazing workforce)

Explore Jobs at The Port House Social Bar & Kitchen

Where did coffee originate and how did it travel?

Wild coffee origins are traced back to Ethiopia to about 850AD. It is interesting to note that primarily only Arabica coffee was known to the world and Robusta made its mark much later in the 1870s. From Ethiopia, Arabica coffee travelled across the world to Yemen, India, Sri-Lanka, and Indonesia. Post the 17th century, it made its way to Europe.

Robusta coffee on the other hand was discovered in the Congo Basin and travelled to Indonesia, India, Uganda, and Ivory Coast where commercial plantations were eventually set up. Robusta reached the American continent around 1912. [1]

From a coffee seed to a coffee tree

The coffee seeds are planted in massive beds or farms. Locations with good sunlight and rainfall make an ideal spot for growing coffee. Based on the variety, it takes about 3-4 years for a coffee tree to start bearing coffee cherries. These are fruits that are often bright red when harvested. It is either picked by hand or mechanically. For good quality coffee, often cherries are hand-picked by expert collectors. [5]

Understanding the coffee bean

Coffee beans come from a certain fruit known as Coffee Cherry. Each Coffee Cherry contains two identical beans. Coffee Cherry is composed of: [3]

- Epicarp: Outer skin which is smooth in its texture. It is known to change its colour from green to deep red as it ripens.

- Mucilage: Light yellow fibrous pulp within the cherry

- Parchment: Thin yet relatively hard yellow layer right above the seed coat

- Silverskin: seed coat surrounding the bean

- Coffee Bean: Coffee bean used for the beverage

What is the difference between pulp and mucilage?

It is often difficult to differentiate between the two. Pulp and mucilage removal are key elements to processing coffee. In the most practical understanding of these tissues, the portion of the fruit that comes out during pulping is called the pulp. In botanical terms, it would be referred to as “exocarp or outer mesocarp”. The sticky substance that remains attached to the parchment after the pulping is called mucilage, in other words, the inner mesocarp.

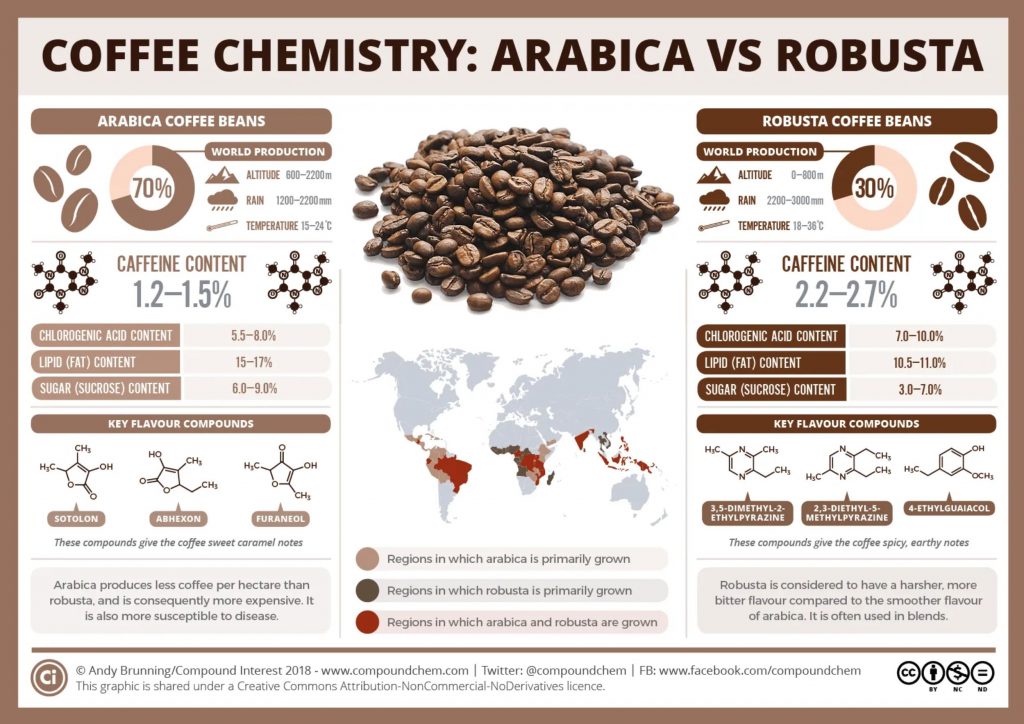

Arabica vs. Robusta

Commercial coffee is broadly categorized into two types namely Coffea arabica and Coffea canephora, usually known as arabica and robusta. Arabica accounts for 60% of the world’s total coffee production. [2]

Arabica coffee beans are high in quality and value. They grow in elevated locations usually 1000m or more above sea levels. The temperatures for growing Arabica range between 20-24 °C with an estimated rainfall of greater than 1200 to 1500 mm per year. They have a soft fruity taste with a certain amount of sweetness. This coffee is usually utilized in roast and ground coffee products and is generally blended with Robusta to improve the coffee quality, especially instant coffee. Countries such as Columbia and Brazil are known for producing this coffee type. [2]

Robusta on the other hand is low in quality and value. They grow in lower elevations and warmer climates. Robusta is strong, harsh, grain-like and nutty in taste. This is supported by the composition of robusta. Green robusta seeds contain almost double the amount of caffeine in comparison to that of Arabica. It has more chlorogenic acids and less trigonelline. It grows in Vietnam, Indonesia and parts of Brazil. [2]

How is coffee processed?

The flavour and quality of a coffee brew depend on genetic factors, climatic conditions, geographical locations, soil conditions, cultivation methods and post-harvest processing. These post-harvest processing methods elevate the qualities of beans in terms of acidity and body. There are two major processing methods namely dry and wet. However, the most important thing to notice here is that any of the processes utilized focuses on one of the three factors: water quantity, oxygen or microbes. [4]

In the dry method, the fruit is dried with the mucilage and skin intact. This method is one of the most original processes wherein the ripest, freshest and most developed coffee cherries are picked and let to be dried under natural and sunny conditions on an elevated bed. This method could take about 3-4 weeks. The cherries have to be observed continually as natural fermentation starts taking place given the environmental conditions.

Fermentation could result in mould growth and therefore, continuous rotation of the cherries needs to take place and quality needs to be monitored. After the fruit is dried, it is run through a hulling machine that gets rid of the fruit and parchment layer. The bean resulting from this process consists of heavy body, sweet flavour and complex attributes. The resulting taste of these beans is fruity, whiney and fermented. [4][6]

Drying of coffee beans

In the wet method, the coffee is harvested ripe when the coffee is dark red, bright red, purple or yellow. After being picked, the coffee cherries are immediately washed. The pulp is then removed by a de-pulping machine. Depulping happens within 8-12 hours post the harvest. After de-pulping, the seeds are still covered in mucilage. Mucilage is removed by natural fermentation which lasts between 12 to 24 hours. Fermentation takes place either underwater or without any added water. Underwater fermentation boosts acidity and aroma and reduces astringency. After fermentation, the coffee is given a thorough wash by agitation. Right after, the coffee is brought to a sorting table and any damaged beans or remaining coffee husks are removed. Eventually, the coffee is laid out on a humongous drying patio and left to dry. The drying environment is designed to control the temperature and airflow to dry the coffee efficiently while preserving the quality. They are left to dry for about one to two weeks until the coffee moisture reaches 11%. Parchment layer is eventually removed when the coffee is ready to be shipped. It is kept until then to prevent the coffee from moisture and temperature fluctuations. [4][6]

A combination of both wet and dry methods happens when coffee is processed by either pulped natural or honey process. The skin of the coffee cherry is removed. Mucilage is partially removed for partial fermentation at the drying stage. Drying time is about 2-3 weeks depending on the weather. The colors of the coffee can vary from yellow to red to black. These different types of coffee also hold a different profile. Yellow tends to be the mildest in terms of fruitiness. Red tends to have bigger fruit flavours and sweetness as well as a noticeably more syrupy body. Black has a whiney and creamy body. [4][6]

A fourth kind is a wet-hulled process. It is a special post-harvesting process specifically practiced in Indonesia. It is practiced due to the damp, cloudy and humid conditions within the country. The coffee cherries are de-pulped within an 8-12 hour window after harvesting. The seeds and the mucilage are then placed in a fermentation tank overnight. After which they are left dry until the moisture reaches 30-35% (semi-dry state). Next, the process of wet hulling takes place where the parchment layer is removed before the seeds are fully dry. This is done using a machine. Given the humid climatic conditions in Indonesia, it is difficult to dry the coffee covered in parchment layer. Removing this layer, while the seeds are still wet allows the coffee to dry efficiently. They are then left to dry again until the moisture comes down to 11%. Coffee processed this way has an earthy, savoury and herbaceous flavour. [4][6]

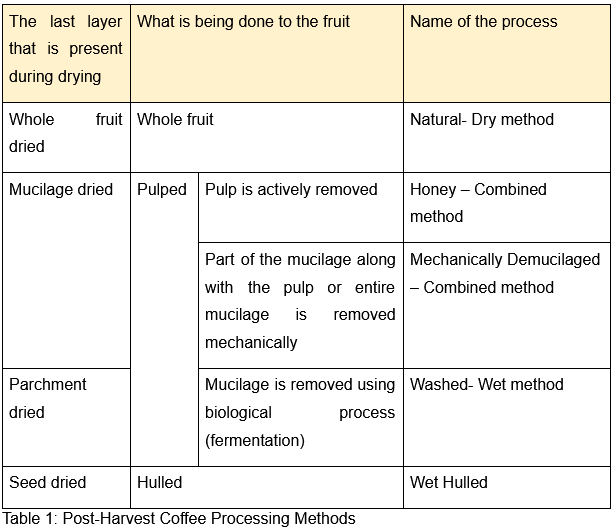

Below is a table that summarizes all post-harvest processing methods.

It is important to note that these post-harvesting methods could differ in steps depending on the processing conditions employed by the owner of the coffee farms.

Drying results in a moisture level of 10-12% in beans. This is an important step as if not carried out properly, it could deteriorate the quality of the beans. Robusta is usually processed using dry methods however India uses wet methods for it. [4]

Coffee processing is quite a complex method and we believe one post does not justify the hard-work, effort and science that goes behind this beautiful commodity. So please await part II of this coffee journey to learn more about coffee quality (cupping and grading) and roasting and much more.

About the Author

I am Anjali Patel, I come from India and completed my Masters in Food biotechnology from Wageningen University in the Netherlands before moving to Canada. Currently, I am working as an intern with Rainfed foods as an innovation and research associate. If not discussing food, you will see me reading books or chasing travel blogs to plan my next holiday.

Subscribe to our newsletter for details on mentorship sessions, workshops, webinars, as well as career and job fairs across Canada and the US!

References:

[1] Herrera, J. C., & Lambot, C. (2017). The Coffee Tree—Genetic Diversity and Origin. In The Craft and Science of Coffee (pp. 1-16). Academic Press.

[2] Winston, E., Op de Laak, J., Marsh, T., Lempke, H., & Chapman, K. (2005). Arabica coffee manual for Lao-PDR.

[3] Adams, M., & Ghaly, A. E. (2007). Maximizing sustainability of the Costa Rican coffee industry. Journal of Cleaner Production, 15(17), 1716-1729.

[4] Sanz-Uribe, J. R., Menon, S. N., Peñuela, A., Oliveros, C., Husson, J., Brando, C., & Rodriguez, A. (2017). Postharvest Processing—Revealing the Green Bean. In The Craft and Science of Coffee (pp. 51-79). Academic Press.

[5] National Coffee Association. 10 Steps from Seed to Cup. Ncausa.org. Retrieved 1 February 2021, from https://www.ncausa.org/About-Coffee/10-Steps-from-Seed-to-Cup.

[6] Cafe Imports. “Coffee Processing” Andy Reiland with narrations by Ever Meister. 6th June, 2019, https://www.youtube.com/channel/UCT4Fu4eGQbDpmZHPNKOQLSQ/about

Images:

From cherry to beans | Soukthavy SAYASOUK| Canva

Drying of coffee beans | Ideation | Canva

Coffee Cherry | Vinh.dav | Canva

leave your comment