The Making of Maple Syrup

Last Updated on February 17, 2023

Canada’s obsession with maple syrup clearly reflects in the record high production numbers of 14.3 million gallons in 2020. [1] Interestingly, Canada accounts for 75% of maple syrup production globally with Quebec leading the harvest. [2] Maple syrup undoubtedly brings Sunday breakfast glee however what is really going on behind that sweet source of happiness?

Maple syrup is extracted from the sap of the maple tree and eventually concentrated by thermal evaporation and reverse osmosis. The dominating sugar in the product is sucrose. The production is affected by multiple factors such as the environmental conditions, microbial conditions in the sap, storage as well as packaging of the final product. It is believed that Native Americans noticed birds poking holes into the sap of maple trees or saw the birds feeding on drops of sap oozing out from broken twigs. This led to the discovery of the sap which was eventually boiled down to form maple sugar. [3]

What is the maple sap and how is it released?

Sap is a fluid that flows inside the tree. The release of the sap is a result of both physical and osmotic forces. As for the physical forces, a significant drop in temperature is observed especially during the freezing season. This results in the freezing of the water vapour present inside the lumen and gives a frost like formation on the inside of the cell wall. The vapor pressure is lower over ice in comparison to that of liquid water and this results in a vapour pressure gradient. Due to this gradient, water is pulled up through the vessels into the lumen where it continues to freeze. Gradually, the entire wood along with the sap starts to freeze. Freezing takes place at the top of the tree (in the branches) and progresses downward. The amount of water that is taken up by the tree in this process is dependent on the soil availability as well as the rate of freezing. [3]

During the warming phase, the frost layer starts to thaw and the gas bubbles start to expand. This results in an increased sap pressure which may reach as high as 40 psi (275 kPa). The pressure eventually starts to drop when the sap is forced out of the cuts or wounds in the tree. Companies tap deliberate holes in the trees to collect the sap. Each taphole releases about 10-20 gallons of sap depending on the conditions during the flow. The sap that is collected is processed further by industries to make the syrup.[3] As for understanding the role of the osmotic forces, further research needs to be conducted.

What conditions affect the sap and its flow?

Temperature fluctuations definitely play a huge role in the development of the sap. Additionally, the flow rate as well the yield of the sap depends on the size and the sugar content of the tree and the pressure gradient. It also depends on the collection technique employed by the company.[3]

How is the sap collected?

The sap is collected in aluminum or galvanized buckets or plastic bags. They can even be collected in a network of plastic tubings. Here, the tubing is connected to larger tubing and eventually to a holding tank. The holding tank is located at the processing site of the maple sap into syrup. A good tubing system with a vacuum can yield up to 25 gal per tap every season.[3]

How is the sap processed?

The sap is eventually concentrated to give maple syrup. This concentration is the result of evaporation by heating and reverse osmosis followed by heating.[3]

The evaporators used in this process contain two pans namely front and back with oil being utilized as fuel. Sap enters the back pan and flows through a feed pipe around the back pan. Here, the sap gets concentrated to about 11-15%. The sap eventually moves to the front pan via a pipe that connects both the pans. In here, the sap flows through multiple partitions further increasing in density, color and flavor. It eventually leaves the evaporator at the drawoff at the intended density and closes again when the density falls below that number. Finished syrup is finally filtered through a pressure filter using diatomaceous earth as media. When the sap enters the system, the sugar content is 2°Bx, whereas the processed maple syrup in the evaporator exits at around 66-67°Bx. (°Bx or Brix stands for measure of amount of dissolved solids.)[3]

What impact does reverse osmosis have on the processing of maple sap?

To fight the high cost of fuel utilized in the process of evaporation, reverse osmosis (RO) is used by some maple producers to increase the concentration of sugar in the sap before it undergoes boiling. Sap processed by reverse osmosis is referred to as “concentrate” and is slightly yellow in color. The reason to opt for this strategy is to utilize less energy for the evaporation process that follows. Interestingly, the by-product (permeate) of reverse osmosis is used to clean the evaporator.[3]

According to a study conducted in 2020, by using sucrose solutions as an analogue for maple syrup, it was concluded that by using reverse osmosis to pre-concentrate maple syrup, reduces about 85% energy costs and 91% energy requirements. The most optimal concentration of the sap achieved by this process was 32% at 50 bar. However, this is likely to reduce when scaled up due to the higher costs of using a high pressure RO system. [4]

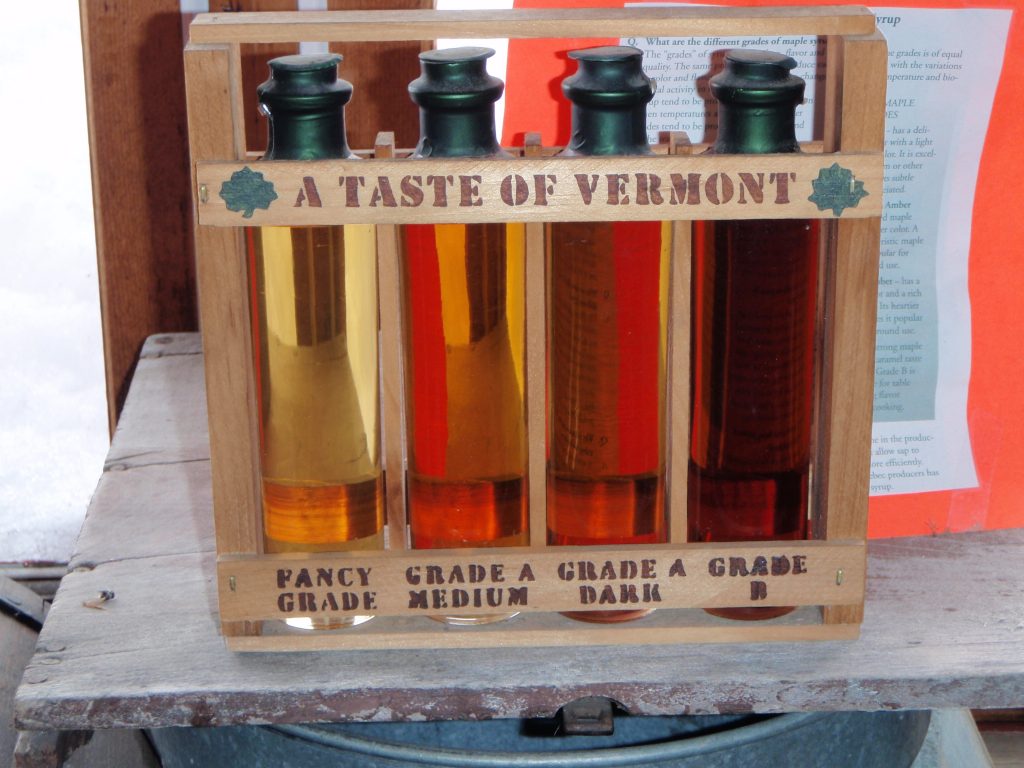

Why are maple syrups made up of different shades of brown?

With the processing of the sap in the evaporator, the syrup starts to darken due to non enzymatic browning. The color depends on the chemistry of the sap as well as the processing conditions. Generally, the more the heating, the more the impact on flavor and color. However, as for the sap chemistry, syrups low in invert sugar concentration produce a lighter color.[3]

For a product to be suitable for the market, it needs to follow a strict set of guidelines. These include factors such as density, clarity, color and flavor. For instance, the total solids in the product should not be less than 66% and should be clear of any particulates. Syrup is furthermore graded based on color and flavor as per a standard chart set by both the USA and Canada. A Flavor Wheel For Maple Products is also utilized which helps determine the flavour gradation of the syrup based on 13 different flavours. [3]

The impact of packaging on maple syrup

Usually, maple syrup is packed at 180-185°F into retail containers. The most commonly used containers are either tins, glass or plastic. Glass retains the color and flavor for over 6 months when kept cold. Plastic packaging sees darkening of the syrup over time however flavor is unaffected. Tin retains the best color however it could have impacts on the taste in the long run.[3]

Issues of adulteration

Maple syrup is costly in comparison to other sugar alternatives. Therefore, there have been incidents of adding cane, corn or beet sugar to maple syrups. The most utilized initial screening method to determine such incidents is by checking the conductivity of the product. If it exceeds 1200 ?S/cm, the product is tested further. Multiple methods are utilized for further determination such as carbon stable isotope ratio test (SIRA), FT-Ramen, and NIR Spectroscopy.[3]

What other products can be made with maple?

Multiple other products are made with maple such as maple cream/butter (not a dairy product), maple candy, maple block, maple sugar etc. Additionally, maple sugar and syrup are also used as flavouring agents in some instances.[3]

Climate changes and its impact on maple syrup

A study was conducted in 2016 to determine the impact of warmer climates on maple syrup production in the USA. This study concluded that with increasingly warmer climates, the habitat of maple trees is likely to be severely affected. The results of this could be less maple sap production per tree and the need for additional (5 million taps according to 2017 projections) taps to keep up with the production needs. [5] Strategies to deal with these changes are already being worked upon in New York and Vermont where maple producers either start tapping earlier in the season or have started using technologies such as vacuum systems.[6]

Maple syrup will forever be a symbol of happiness for Canadians. The next time you drizzle that syrup onto those pancakes, do remember the strenuous hard work that goes behind its making.

About the Author

I am Anjali Patel, I come from India and completed my Masters in Food biotechnology from Wageningen University in the Netherlands before moving to Canada. Currently, I am working as an intern with Rainfed foods as an innovation and research associate. If not discussing food, you will see me reading books or chasing travel blogs to plan my next holiday.

Subscribe to our newsletter for details on mentorship sessions, workshops, webinars, as well as career and job fairs across Canada and the US!

References:

[1] The Canadian Press Staff (2020, December 10) Maple syrup harvest hits record high in 2020; sales also rise. CTVNews. Retrieved 10 January 2021, from https://www.ctvnews.ca/business/maple-syrup-harvest-hits-record-high-in-2020-sales-also-rise-1.5225678

[2] Statistic Canada (2020, April 11) Statistical Overview of the Canadian Maple Industry, 2019 – Agriculture and Agri-Food Canada (AAFC). Agr.gc.ca.Retrieved 10 January 2021, from https://www.agr.gc.ca/eng/horticulture/horticulture-sector-reports/statistical-overview-of-the-canadian-maple-industry-2019/?id=1604326674902.

[3] Perkins, T. D., & van den Berg, A. K. (2009). Maple syrup—Production, composition, chemistry, and sensory characteristics. Advances in food and nutrition research, 56, 101-143.

[4] Weaver, N. J., Wilkin, G. S., Morison, K. R., & Watson, M. J. (2020). Minimizing the energy requirements for the production of maple syrup. Journal of Food Engineering, 273, 109823.

[5] Matthews, S. N., & Iverson, L. R. (2017). Managing for delicious ecosystem service under climate change: can United States sugar maple (Acer saccharum) syrup production be maintained in a warming climate?. International Journal of Biodiversity Science, Ecosystem Services & Management, 13(2), 40-52.

[6] Kuehn, D., Chase, L., & Sharkey, T. (2017). Adapting to climate change: Perceptions of maple producers in New York and Vermont. Journal of Agriculture, Food Systems, and Community Development, 7(3), 43-65.

Image references:

The Fruits of My Labor | John Munt

Sugaring Off Time In Maine | Paul VanDerWerf

Maple Syrup |ckowalik

leave your comment