Allergens in Food Manufacturing

Last Updated on February 22, 2023

Being a Chemistry student I never had formal education when it came to food safety matters. Obviously, I knew that allergens were an issue in the food world. Some individuals have allergies so severe that it could cause death.

Coming out of a school my first job has been working at at snack manufacturing plant. We primarily work with nuts like peanuts and tree nuts but the plant manufactures other products such a mixes of food products which contain some of the major allergens. Working in this type of environment has taught me so much about allergens and today I thought I would share what I have learned with you.

According to the Food and Drug Administration, more than 160 foods can cause allergic reactions. The eight foods that account for 90% of these reactions are milk, eggs, fish, crustacean shellfish, tree nuts, peanuts, wheat and soybeans.

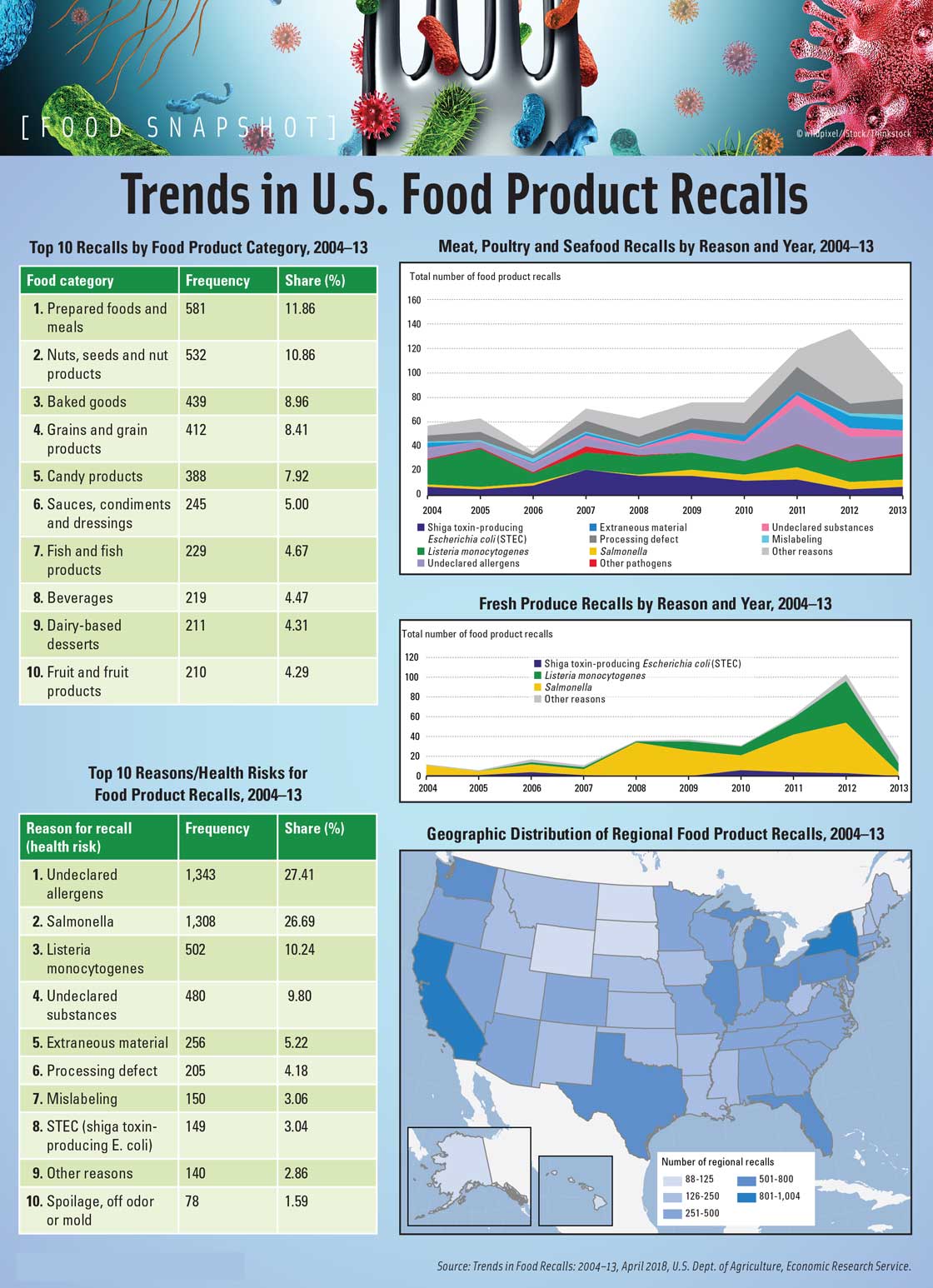

Allergens are the number one reason for recalls…

The number one reason for food safety recall from the years 2004-2013 was not food borne illness but actually food allergens. According to the U.S Dept. of Agriculture, Economic Research Service, 27.41% of the total reasons/health risk for food product recalls was undeclared allergens. This is an astounding number considering allergens are something that we have the ability to control.

Source: Trends in Food Recalls: 2004 13, April 2018, U.S. Dept. of Agriculture, Economic Research Service.

What is a food allergy?

A food allergy is defined as a form of adverse reaction to food in which the cause is an immunological response to a food. Food allergies occurs when a food is considered harmful to someone’s body. Although most food allergies cause relatively mild and minor symptoms, some food allergies can cause severe reactions, and may even be life-threatening.

Symptoms include:

- Hives

- Flushed skin or rash

- Tingling or itchy sensation in the mouth

- Face, tongue, or lip swelling

- Vomiting and/or diarrhea

- Abdominal cramps

- Coughing or wheezing

- Dizziness and/or lightheadedness

- Swelling of the throat and vocal cords

- Difficulty breathing

- Loss of consciousness

The difficulty with food allergies is that we still have a poor understanding of the mechanisms behind food allergies. There is no cure for food allergies and strict avoidance is the best practice for managing food allergies.

Adverse reactions to food

Reactions to a food can be subdivided into two different sections.

1. Generic- May occur in anyone who consumes sufficient quantity of the food. They can be toxic like consuming arsenic or bacterial. Or they can be pharmacologic like consuming caffeine.

2. Specific- Occurs in only certain individuals intolerant to specific food components.

The first type of specific adverse effect to food is aversion. This occurs when someone has a mainly psychosomatic adverse response to food. Psychogenic food reactions may include anger, anxiety, anorexia, depression, euphoria, feelings of security, guilt, hostility, passive-dependent attitudes, pleasure, syncope, and relaxation.

The second type is allergic food hypersensitivity which is immunologic mechanisms defined or strongly suspected. This is what categorizes food allergies and where things like peanut allergies and coeliac disease fall under.

The final and third specific adverse reaction to food is a non- allergic food hypersensitivity in which immunologic mechanism is excluded. They are metabolic disorders which include lactose intolerance, phenylketonuria and favism.

How do food manufactures detect allergies?

There are three types of tested used in the detection allergens: 96-well assays (ELISAs), swab and lateral test kits.

- ELISAs– These tests are expensive but are the best at providing quantitative results. Enzyme-Linked Immunosorbent Assay (ELISA) uses a solid-phase enzyme immunoassay (EIA) to detect the presence of a ligand (commonly a protien) in a liquid sample using a single or a pair of antibodies.

- Swab kits- simple and east to use. These methods yield qualitative results at 5 ppm and are often used to assess cleanliness of equipment. These tests are meant for inplant use.

- Lateral-flow devices – These test generally only show you whether or not the test have the the qualitative amount of the product reaching the threshold. For example, if a lateral- flow test is designed to five a positive or negative result at a level of 5ppm and the dipstick shows a line indicating the presence of the allergen. You don’t know just that if line appears fast, the level is higher.

- Other tests- polymerase chain reaction (PCR) and ATP

Check out this actual product used in manufacturing plants!

How to prevent cross-contamination in food manufacturing plants?

There are many combined ways that manufacturing plants can prevent cross-contamination during production. Human error is only one factor that predisposes risk of cross-contact; product timing, processing lines, facility traffic, protein structure and even the equipment used can be a game changer when it comes to proper handling of allergens.

- Staff Training and Education- In order to have an effective allergen program all plant, production staff, contractors and visitors must be aware of the importance and its importance on consumers.

- Processing- Cleaning is the most common sense way of preventing cross-contamination. To pump a cleaning regime plant employees should be assigned to specific locations to avoid risk of cross-contact level- color coding uniforms. How well individuals clean should be validated using a recognized protein-specific test methods.

- Production planning- Production runs should always be scheduled beginning with formulas with least amount of allergen and moving to those with more allergens. That being said “may contain” or “produced in a plant that handles” should not be used as an excuse for poor good manufacturing practices.

- Cleaning and Sanitation- Effective cleaning methods depends on the surface, type to be cleaned, the contamination type (liquid, powder etc) and Stainless steel surfaces are usually much easier to clean since they are smooth. Plastic surfaces are easily cleaned when they are new and in good condition.

Author: Veronica Hislop Veronica is a recent FoodGrad working as Quality Assurance Technician at a snack food company. She graduated with a Chemistry degree at Ryerson University and has a passion for bringing awareness to sustainability in the food industry. When Veronica is taking a break from her food endeavours you will find her at home reading a great novel and playing with her cats.

Subscribe to our newsletter for details on mentorship sessions, workshops, webinars, as well as career and job fairs across Canada and the US!

leave your comment