Cold Plasma in Food Processing: Science, Uses, and Benefits

Last Updated on September 3, 2025

You may remember learning about the three states of matter in basic chemistry: solid, liquid, and gas. However, there is another state known as plasma. While plasma can occur naturally in phenomena such as lightning strikes and neon lights, it can also be artificially created for various uses, including those in the food industry. Cold plasma (CP) is an innovative food processing technique that aims to refine food safety. The functionality, applications, advantages, and drawbacks of cold plasma technology have attracted considerable attention, and this article will explore each of these aspects in detail.

Figure 1: Microwaving grapes until they ignite fire is an example of plasma. (Khattak et al., 2019)

What is Cold Plasma?

Plasma can be described as a gas-like state consisting of charged particles that are in rapid and random motion, with weak intermolecular forces occupying the volume of their container. The key difference between plasma and gas is that in plasma, the atoms become electrically charged, causing electrons to be pulled away from their nuclei. This results in oscillating and magnetic fields affecting the energy levels and movement patterns of the electrons.

How is plasma generated?

The method used to generate plasma determines its type, resulting in two main categories: low-temperature plasma (non-equilibrium) and thermal plasma (equilibrium). At an extremely elevated temperature of 20,000 K, thermal plasma is created which is composed of charged electrons, gas particles and ions. Additionally, thermal plasma is characterized by a temperature equilibrium, where the entire composition is similar in temperature, regardless of its size. On the other hand, low-temperature plasma operates at a much cooler temperature, ranging from approximately 0 to 50 °C. Also known as non-equilibrium because the plasma’s gas molecules and electrons may be at different temperatures. Since gas molecules are “cooled,” they tend to remain cool and utilize energy from predominantly electrons to create reactive molecules that attack microbes.

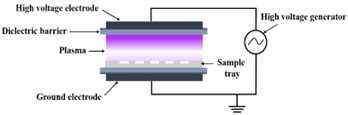

There are several methods for creating plasma, including the dielectric barrier method. The dielectric barrier discharge requires a high-voltage generator, two flat electrodes, and electrical insulators. Generators in circuits supply electrical energy and insulators prevent short circuits. An inert or neutral gas enters a closed chamber and becomes ionized, yielding plasma.

Food Production and Cold Plasma

Cold plasma has traditionally been used in the medical and polymer processing industries. In recent years, interest has shifted toward its use in the food industry, where researchers are exploring its potential to improve food safety and quality. This technology offers a way to protect temperature-sensitive products from heat damage during sterilization. Traditional thermal processing can compromise the sensory qualities of food, resulting in nutrient loss, color changes, and textural differences. By contrast, cold plasma processes utilize electric fields, offering a non-thermal alternative. Most research and development in food applications is conducted by universities, physicists, engineers, and private companies. However, creating and implementing this technology is complex, requiring high-voltage power supplies, plasma generators, and specialized materials.

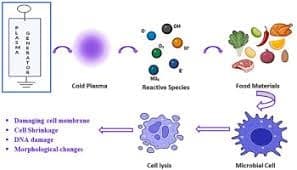

Figure 2: CP and Food Processing. (Harikrishna et al., 2023)

To understand how cold plasma achieves its antimicrobial effects, it helps to consider the process at the molecular level. The treatment begins with ionization of various gases such as helium and hydrogen. Ionization means that gas molecules lose electrons and become charged particles (ions). They make contact with electric fields and ionize at low temperatures, hence the term “cold.” Next CP forms where its main composition includes free radicals, active molecules, ions, and atoms. Afterwards, CP is ready to cause cell lysis, DNA damage and decrease the size of cells. Microbial activation occurs because contaminated food surfaces come into contact with products. Additionally, CP has electromagnetic fields that cause electrostatic forces to condense at the highest energy point on microbial cells. Consequently, the rapid cellular bombardment causes plasma etching, where there is rapid DNA and chemical denaturation which leaves bacteria incapable of repairing fast enough (cell death). Thanks to the chemically active products formed, plasma may act as an antimicrobial by interacting with the surface of living cells of microorganisms, thereby preserving food.

Figure 3: Dielectric barrier discharge schematic. (Sawangrat et al., 2025)

Benefits of using plasma in food production

Cold plasma is gaining recognition in the food industry for its ability to address many challenges associated with traditional processing methods. Its key benefits include:

- Improved textural properties: While high-temperature treatments used for sterilization can compromise food quality, CP preserves the desired texture. For example, while blueberries may become softer during heat treatment, CP helps maintain their firmness.

- Enhanced food safety: CP effectively eliminates sporulating and deteriorating microorganisms in cereals, vegetables, and meats, providing a reliable method for decontamination. It can also be used as a disinfectant for both food surfaces and packaging materials.

- Increased processing efficiency: When paired with heat treatment, cold plasma can reduce heating times, thereby preventing unwanted protein denaturation and non-enzymatic browning. This approach helps preserve the nutritional content of foods such as milk, provided reactive compounds are removed after treatment.

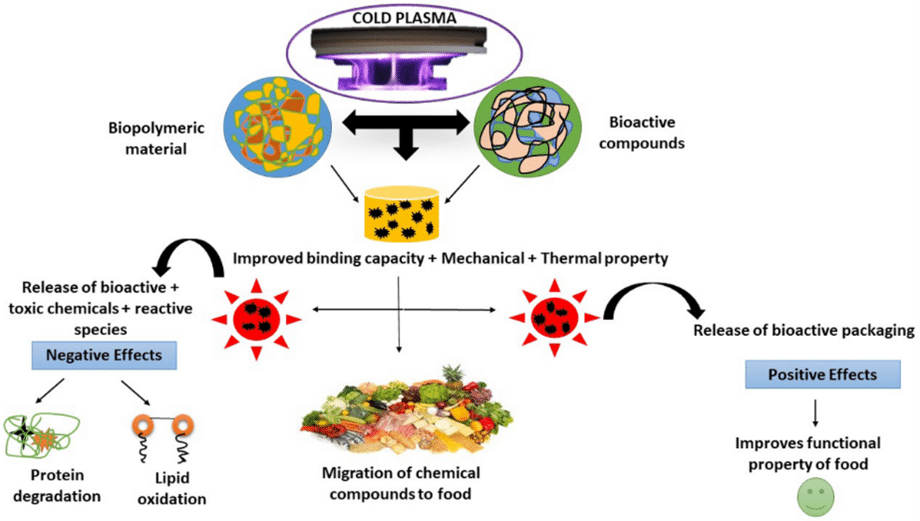

Figure 4: Food processing positives and benefits of CP processing (Farooq et al., n.d)

Challenges of cold plasma treatment in food processing

Despite the significant promise of cold plasma treatment in the food industry, several important challenges remain and require further investigation. The following barriers have been identified:

- Sensory issues: Foods tend to increase in acidity, influencing firmness, loss of pigmentation and organoleptic alterations when CP processing is applied.

- Lipid oxidation: Oxidation is known to accelerate with CP processing, resulting in increased levels of reactive substances. This is primarily due to the generation of reactive oxygen species and reactive nitrogen species. These unstable molecules readily attack the double bonds of unsaturated fatty acids, initiating lipid auto-oxidation and producing lipid peroxides. Literature reports have shown increased levels of thiobarbituric acid reactive substances (TBARS) in products treated with cold plasma, particularly when argon and oxygen are used as feed gases. The heightened TBARS values are consistent with the oxidative degradation of lipids triggered by ROS and RNS formed during plasma treatment.

- Protein oxidation: Proteins within treated foods are also susceptible to oxidation by reactive species. This can reduce both nutritional quality and digestibility. Proteins also oxidize due to these reactive species, denaturing meat proteins. Proteins contain a main chain of amino acids and side chains of amino acids that may be oxidized by the reactive species. Often creating protein cross-linkages that may deteriorate meat quality, solubility, and texture.

Conclusion

On the whole, CP is a revolutionary and non-thermal food processing technique that enhances the shelf-life stability of foods. While it is widely implemented in the health sector, CP has the potential to become a universal food processing technique with further advancements. Despite its global promise to improve food safety during production, the benefits do not completely outweigh the shortcomings. There is still a significant need for research to address concerns about genotoxicity and the potential negative consequences of oxidation.

Image References

Figure 1 – Khattak, H. K., Bianucci, P., & Slepkov, A. D. (2019). Linking plasma formation in grapes to microwave resonances of aqueous dimers. Proceedings of the National Academy of Sciences, 116(10), 4000–4005. https://doi.org/10.1073/pnas.1818350116

Figure 2 – S. Harikrishna, Pawase Prashant Anil, Shams, R., & Kshirod Kumar Dash. (2023). Cold plasma as an emerging nonthermal technology for food processing: A comprehensive review. Journal of Agriculture and Food Research, 14, 100747–100747. https://doi.org/10.1016/j.jafr.2023.100747

Figure 3 – Choncharoen Sawangrat, Kittisak Jantanasakulwong, Suhr, J., Kannikar Kaewapai, Thidarat Kanthiya, Parichat Thipchai, Pornchai Rachtanapun, & Pitiwat Wattanachai. (2025). Synergistic Effects of Dielectric Barrier Discharge Plasma Treatment on Hemp Fiber Surface Modification and Mechanical Properties of Hemp-Fiber-Reinforced Epoxy Composites. Applied Sciences, 15(5), 2818–2818. https://doi.org/10.3390/app15052818

Figure 4 – Farooq, S., Dar, A.H., Dash, K.K. et al. Cold plasma treatment advancements in food processing and impact on the physiochemical characteristics of food products. Food

Comments are closed